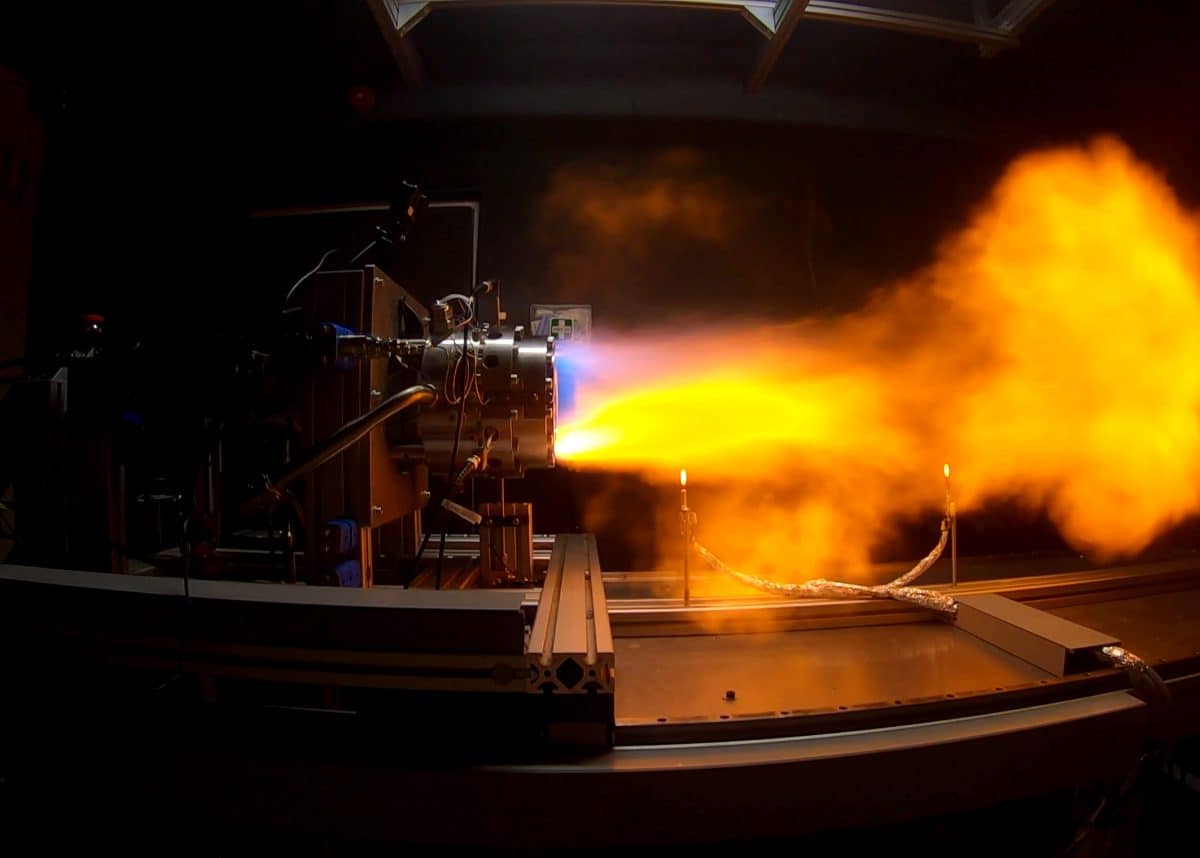

An Australian research consortium has successfully tested a next-generation propulsion system that could enable high-speed flight and space launch services. The team’s rotating detonation engine, or RDE, is a major technical achievement and an Australian first.

It was designed by RMIT University engineers in Melbourne and is being developed by a consortium led by DefendTex, an Australian-owned company that services military and law enforcement communities around the world.

Research assistance is being provided by RMIT, University of Sydney and Universität der Bundeswehr in Germany.

While conventional rocket engines operate by burning fuel at constant pressure, RDEs produce thrust by rapidly detonating their propellant in a ring-shaped combustor. Once started, the engine is in a self-sustaining cycle of detonation waves that travel around the combustor at supersonic speeds greater than 2.5km a second.

Can significantly increase engine efficiency

Using this type of combustion has the potential to significantly increase engine efficiency and performance, with applications in rocket propulsion and high-speed air-breathing engines – similar to ramjets.

Benefits over existing engines include better fuel efficiency, simpler flight systems and a more compact engine. This allows for larger payloads and reduced launch costs.

Project technical lead and RMIT University aerospace engineer, Dr Adrian Pudsey, said successful ground demonstrations at the engine test cell, which was custom-designed and operated by RMIT with support from DefendTex, had triggered enormous excitement.

Australia now has a truly unique capability

“To succeed in such an exceptionally challenging project means a lot to everyone involved,” he said.

“Through strong collaboration over the past two years we now have a truly unique capability and have demonstrated the know-how and science required to push the boundaries of this technology even further.”

Pudsey said a major challenge to overcome was keeping the engine from overheating, while the next step of the project involved looking at a fully 3D-printed, actively cooled version of the successful prototype.

Commercial opportunities for space industry

Other challenges, including advanced modelling of the engine’s behaviour and integration of the engine into a functioning flight vehicle, remain to be overcome before proceeding to test flights.

Although this technology is in its early stages, further development could support satellite launches from Australian soil and commercial opportunities for Australia’s space industry, while indirectly supporting telecommunications, agriculture, transport, logistics and other industries.

Among the benefits could be to allow Australia to capture a greater share of the international space launch market.