Richard Bowman, University of Bath and Julian Stirling, University of Bath

In factories and industrial estates across the world, exceptional efforts are being made to ensure hospitals have ventilators, and logistics firms have freezers and refrigerators. Behind the scenes, this manufacturing drive has been taking place on an epic, unprecedented scale. In some places, it’s also been horrendously inefficient.

Some of that inefficiency is only to be expected. Manufacturing responsively at such short notice was always going to be messy. But many of the hardware hold-ups we’ve witnessed – from production line bottlenecks to parts shortages – could be avoided in the future by applying an “open source” ethos to the world’s production of hardware.

Open source design is a form of collective intelligence, where experts work together to create a design that anyone has the legal right to manufacture. The software industry has long shown that “open” collaboration is not only possible, but advantageous. Open source software is ubiquitous, and the servers that power the internet itself are largely run on open technology, collaboratively designed by competing companies.

Early in the pandemic, and in recognition of the global emergency that was unfolding, dozens of the world’s largest companies did actually sign up to the “Open COVID Pledge”, promising to share their intellectual property to help fight the virus. On a smaller scale, more than 100 project teams set out to create and share “open” ventilator designs that could be produced locally, helping address the pressing need for ventilators around the world.

Unfortunately, neither of these initiatives succeeded in producing ventilators at the rate required by stretched hospitals in the early weeks of the pandemic. After examining existing attempts to share the intellectual property of machines, our recent paper concludes that projects must be open from the start in order to make a success of open hardware. Everything from the first doodle on a napkin to the detailed calculations that verify safety must be available if other experts and manufacturers are going to participate in the design.

The road to open hardware

Producing hardware through open collaboration may be daunting. As opposed to the entirely virtual collaboration required for software development, hardware development needs physical parts – raw materials and machinery. It needs testing facilities and engineers to perform stress tests and safety checks.

There are promising signs that these challenges can be met. The RepRap 3D printer project has brought low cost 3D printing to a wider audience, making affordable prototyping possible at a distance. Meanwhile, the CERN White Rabbit project has shown that even the complex electronics that control the Large Hadron Collider can be developed as as open source hardware. But, to be efficient we need better work flows for collaboration – systems to help organise the distribution of tasks and responsibilities on collaborative hardware projects.

The journey from prototype to production is much more difficult, and less exciting, than the technical challenge of prototyping a device. Manufacturers must comply with international standards to ensure quality and manage risk related to their products. This is especially true of medical hardware, upon which lives depend. A key challenge for open hardware will be to achieve this certification in the same way that private companies do today.

Under current regulations, no matter how impressive and safe, ventilators constructed in volunteer maker spaces cannot be certified for medical use. But for equipment which is less strictly regulated, like face shields, open hardware is currently being leveraged successfully.

Achieving similar successes with high-tech medical devices will require organisations that are built to manufacture from open designs – dynamic factories, for instance, which will be responsive to global emergencies. It takes time to establish these organisations. But we can’t afford to wait for the next emergency: we should begin creating them today, in preparation for the next pandemic.

Of course, finding sustainable business models for open hardware is a challenge: can a system be created which shares intellectual property for free while helping designers and manufacturers profit? In one sense, open hardware has an advantage here: people are used to buying products, where online consumers are accustomed to using software for free.

Nonetheless, it’s likely that setting up an open hardware manufacturing ecosystem will need public funding, or investor funding buying into non-traditional business models. This would follow the trajectory of the internet, which began life funded by public institutions and is now home to the world’s biggest private enterprises.

Closer inspection

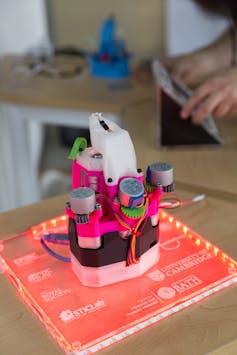

We’ve experimented with our own open hardware project to help us understand how the future of collaborative hardware might look. Our OpenFlexure microscope is designed to be manufactured at low cost in sub-Saharan Africa, to be used for malaria diagnoses. We’ve probably spent more time designing the processes that help us share our knowledge effectively than designing the microscope itself.

In the short term, this slows our progress. In the long term, we expect that manufacturers anywhere in the world will be able to understand our design and adapt it to their local context. As these processes become further standardised, sharing designs for production will become increasingly simple. The final and most ambitious phase of our project will be working with manufacturers to produce microscopes certified for medical use – a huge step towards open source medical hardware we’d need to better fight a future pandemic.

Humanity already knew how to make ventilators decades before this pandemic hit. What was lacking was the access to this knowledge, the skills to work together on adapting a design, and the logistics to rapidly scale the manufacturing of complex machinery. It will take years to address these issues. Starting that process today will help us tackle global emergencies more dynamically and efficiently in the future.

Richard Bowman, Royal Society University Research Fellow and Proleptic Reader, Department of Physics, University of Bath and Julian Stirling, Postdoctoral Researcher, Department of Physics, University of Bath

This article is republished from The Conversation under a Creative Commons license. Read the original article.